Secabo's TP Series heat presses: designed to answer the "wants and needs" of professional high-volume and large-format garment personalisation. The TP Series heat presses are the options you should choose if you need reliable, efficient and high-quality equipment for garment personalisation at scale!

Secabo TPD7 Premium

Secabo TPD7 Premium

Secabo TPD7 Premium

Secabo TPD7 Premium: top performance at high contact pressure, superb heat output, and heat distribution is the standard set by Secabo's TPD7 Premium Automatic Double Plate heat press.

The Secabo TPD7 Premium double plate press delivers innovative, versatile features, automatic pneumatic operation of the pressing head and a modular design. Each 40cm x 50cm base plate allows for transfers with an extremely high contact pressure of 12kN at 10bars (600g/cm2 or 1.2t).

Innovative and ergonomic features aid comfortable and efficient use, including the pre-pressing function with adjustable pre-pressing duration, separately configurable pressing duration for both base plates and saveable sets for pressing time and temperatures. The heating plate with a power consumption of 2.5kW ensures a high heat capacity with professional temperature distribution. The stable base stand creates a comfortable working height, and the footswitch makes it easy to operate the pressing head.

Pneumatic pressure can be easily adjusted and optimised for all transfer objects. And interchangeable components and compatibility with Secabo accessories, quick-change systems, removable plates and membrane base plates deliver further productivity enhancements.

Secabo TPD7 Pneumatic

Secabo TPD7 Pneumatic Double Plate Press: this TPD7 heat press by Secabo is ideal for the professional processing of large-scale and extensive transfers in large editions and supports all commonly used transfer methods.

Compressed air produces the pressure for this double plate heat-press, which means more effortless operation and consistent, reproducible results. In this model, the base plates are portrait to simplify the precise positioning of transfer objects. Each work plate provides a particularly generous working area of 40cm x 50cm for the comfortable positioning of transfer objects. The work surface on each exposed base plate also helps increase the quality and precision of transfers.

In combination with the precise vertical pressure control, the head of the heating plate smoothly aligns horizontally over each work plate for a flawless transfer of various materials without misalignments or similar issues.

Secabo TP10 Pneumatic XL

Secabo TP10 Pneumatic XL

Secabo TP10 Pneumatic XL

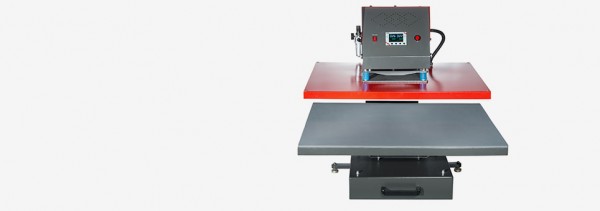

Secabo TP10: the 80cm x 100cm extra-large base plate and super generous work area is the Secabo TP10 Pneumatic XL heat press's standout feature.

Secabo developed the TP10 for professional textile printers. The TP10's supersized 80cm x 100cm work area is particularly suitable for heat transfers on large items such as flags, sheets or textile décor pieces. The base plate also acts as a drawer, allowing easy transfer object handling despite their size.

Compressed air creates the pressure for the TP10 press, which means consistent and reproducible results are straightforward. The heat plate's pneumatic head also guarantees flawless transferring of various materials without displacement effects, etc. With its heat output of 5.1 kW, the Secabo TP10 heat press is suitable for all standard transfer processes in almost all areas of transfer technology.

"Are the above TP Series industrial pneumatic and automatic heat presses a bit too much for what you need? If so, take a look at the other heat press options in the Secabo heat press range. We're confident we have the ideal Secabo heat transfer press for you!"